Whether you are the new MAN the oilpatch, or a tenured LEGEND in the making, unveiling the MYTHical creature of “what is inherent FR” is critical, in order to understand what FRC’s work best for your teams. …and simply how to avoid being duped. The great thing about working with RPS is that we are 100% fabric agnostic. Meaning, we will manufacture your program’s work apparel with the fabric you spec in. The options are limitless. We are here to simply present options, assist in evaluation criteria, and present protective/cost-savings best practices.

INHERENT is defined as “existing as a natural or basic part of something.” This means that FR fabrics can reach “inherent” qualities one of two ways.

First up, is via “synthetic fibers.” Synthetic FR fabrics are made with aramid and/or modacrylic fibers that are automatically flame resistant in their raw state. Typically, these fibers are more durable but can come with a less comfortable “hand,” or feel to the fabric. They also tend to be less affordable than the cotton alternative. A commonly known synthetic fabric is Dupont’s Nomex. There are many more options of synthetic inherent fabrics in the market today, however they remain a viable option for low turnover, downstream business models.

Second, natural-fiber (cotton-based) FR fabrics can be either “treated” or “inherent,” depending on how the FR chemical is applied and when in the process of milling it is applied. Let’s first rule out “treated.” To ease your mind, none of RPS’ CrudeFR fabrics are “treated” with FR chemistry. But to fully educate, treated FR is then 100% cotton or cotton blend FR fabrics are milled and then chemical treatment is applied (think…Scotch-guarding a sofa) in a way that fully saturates the material and is bonded to the outside of the fibers. Typically, in this application, the FR chemical is eventually washed out of the uniform and FR protection is diminished as the uniform wears on. In this case the garment is only as protective as the number of wash cycles, as deemed by the manufacturer.

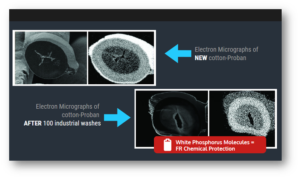

Lastly, are “inherent” FR cotton fabrics. This is typically where the AWE-HA is! For your peace-of-mind, all of RPS’ cotton-blend CrudeFR fabrics are truly inherent. Here, cotton and high-strength bio-fibers are directly polymerized (injected inside the microscopic fibers) with FR chemistry. In RPS’ case, we exclusively use Proban FR chemistry (made by trusted chemical manufacturer, Solvay). Essentially, each cotton fiber is impregnated with Proban to ensure that the FR protection cannot be washed out and it maintains phosphorous for the life of the garment.

Footnote: Electron Micrograph of the FR phosphorous remaining at high levels after the garment has been washed 100 industrial cycles.

- Letter of Recommendation from BP to Solvay, further explaining how Proban’s intrinsic/inherent FR chemistry is game-changing for BP.

2. Letter of validation to Kuwait Oil Company, from Solvay officially declaring both RPS’ CrudeFR 5.4oz lightweight Gridlock fabric (super lightweight and breathable) and 7oz middleweight 7oz fabrics, as inherent.

3. A simple (but serious) reminder that all RPS’ CrudeFR products are globally recognized and UL certified, making them and their raw materials all NFPA2112 compliant.

There is never a day in the FR work apparel business, where we remain unsurprised with what people have been taught about FR care and overall protective value. Still today, workers are washing their work apparel in bleach, using fabric softener and wondering why they experience skin allergens, etc. Furthermore, the most common question asked about FRCs is, “How many washes is it good for, before it is not FR anymore?”

Grimace…Grimace…

The answer is clear. If you choose RPS, you are choosing the ultimate in protection that is good for the life of the garment. But don’t just take our word for it. Instead, trust BP, one of the largest energy champions in our industry. Trust Solvay, a global leader in materials and chemicals, that you likely are purchasing other goods from now. But in the end, trust Underwriters Laboratories (UL). All finished products deeming the UL badge are superior in quality. In essence all compliance risks and gaps have been mitigated for you. Our FR products have been rigorously tested and confirmed that they meet, or exceed all NFPA2112 standard requirements.

Take the guess work out of your FRC decisions and trust RPS to help you navigate the ever-changing technology of FR work apparel.