FLAME RESISTANT CLOTHING SAVES LIVES

WHAT SETS CRUDE FR™ APART FROM THE REST

Our program management goes beyond forecasting. In order to keep 30 days of inventory on the shelves, we forecast 120 days in advance. This allows us to have this month’s finished goods in inventory, the next month’s finished goods in production, and the following month’s raw materials in stock. In addition, RPS has worked hard to create strategic partnerships with our key suppliers to keep raw materials in production for use 120 days later. The unique value that this strategy offers RPS is that there will never be more than 4 months of inventory in process at any given period of time.

Most of our competitors do one of two things:

1. They hedge their production and under-forecast so as not to expose themselves to significant inventory buildup. As a result, this strategy creates the potential for long lead times and delivery as they are always working from behind.

2. Or, they create too much available inventory in order to meet the required shipping timetable, which in turn creates significant liability to both them and their customer, especially if demand decreases for any reason.

In addition to our forecasting strategy mentioned above, we own all elements of manufacturing for the majority of work apparel. With our distribution center in Del Rio, Texas, located just two miles from our manufacturing plant in Acuña, Mexico, we not only cut cost and time overall, but we are able to ship items produced on the same day for emergency situations. We also carry the advantages of dexterity and customization to client needs—from custom sizing to modified production schedules to accommodate a sudden hiring surge.

Interested in our Managed CrudeFR Uniform Programs?

of industrial uniforms.

GOOD, BETTER, BEST

The top priority for FR uniform program decision-makers:

But what exactly are the GOOD, BETTER, BEST

FRC options to measure uniform priorities?

Every time you fuel up at the pump, you are evaluating your priorities.

HOW IT WORKS

Owning both manufacturing and distribution of our products allows us the dexterity to react to client needs and market changes efficiently in both time and cost. During market changes that drastically affected client work apparel needs over the last four years, we have:

- Increased and decreased production lines as needed.

- Fluctuated staff numbers accordingly.

- Offered overtime to day shifts and even instituted evening shifts to add more production capacity.

- Partnered with other manufacturing plants in Mexico to supplement our own production. We treat these partnerships like in-house manufacturing, applying the same rigorous quality control and continuous improvement expectations and oversight.

- Especially in times of unexpectedly increased production, we quickly realigned forecasting with new market conditions.

The RPS Solutions team thrives on turning challenges into successes for our clients so they can focus on their business goals. In short, we pride ourselves on taking your work apparel program off your plate.

SUPPLY CHAIN SUCCESS STORY

“This spring, one particular client placed stock orders for new hire classes that were three times larger than expected—then called us to ask that each order be filled within 24-48 hours. While our shipping strategy is 3-11 business days, we had the majority of items in stock each time, and we were able to ship 90-100% of each order of over 65 items. We promise 3-11 days because our business model is structured to fulfill that commitment, but our forecasting strategy often allows us to exceed expectation in exceptional situations.”

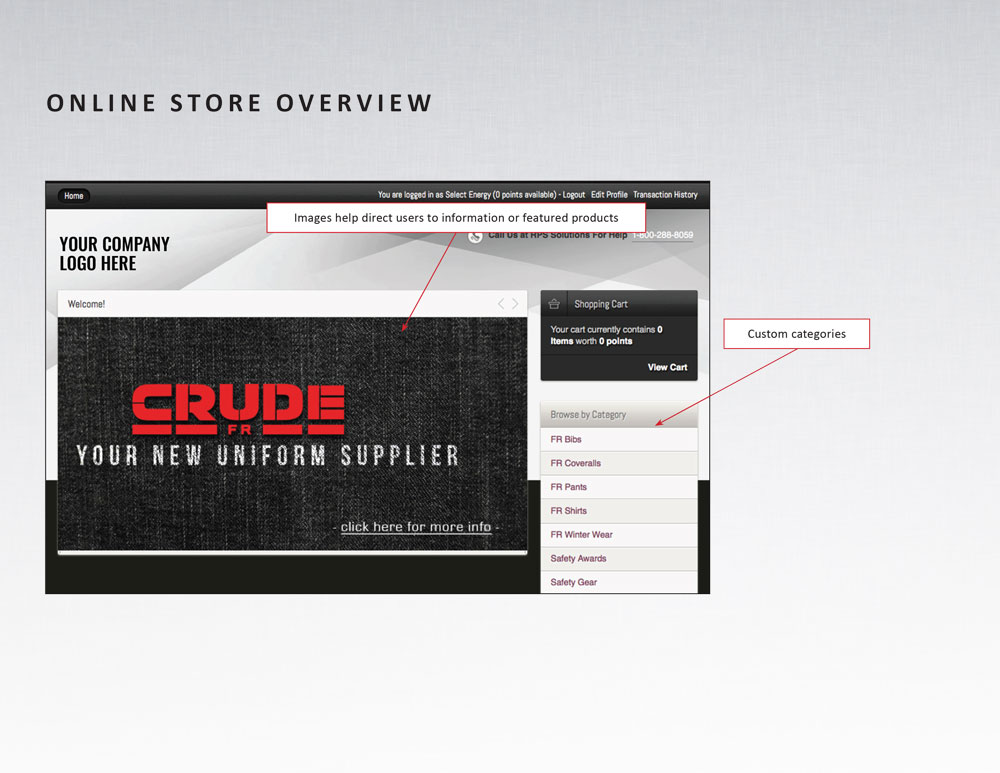

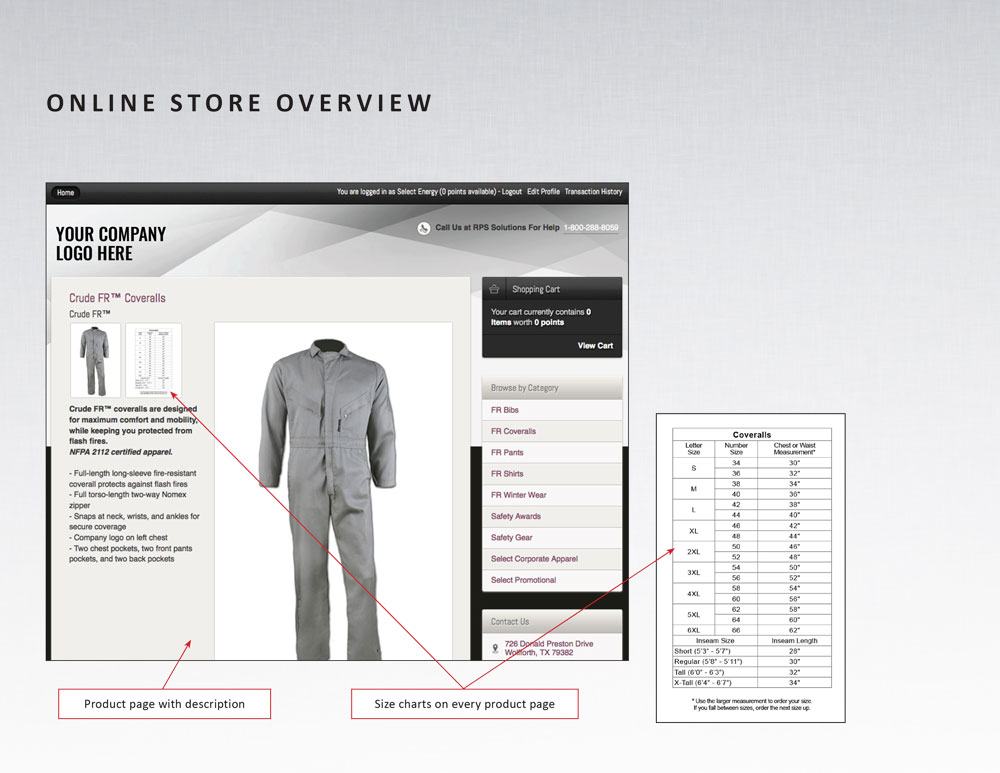

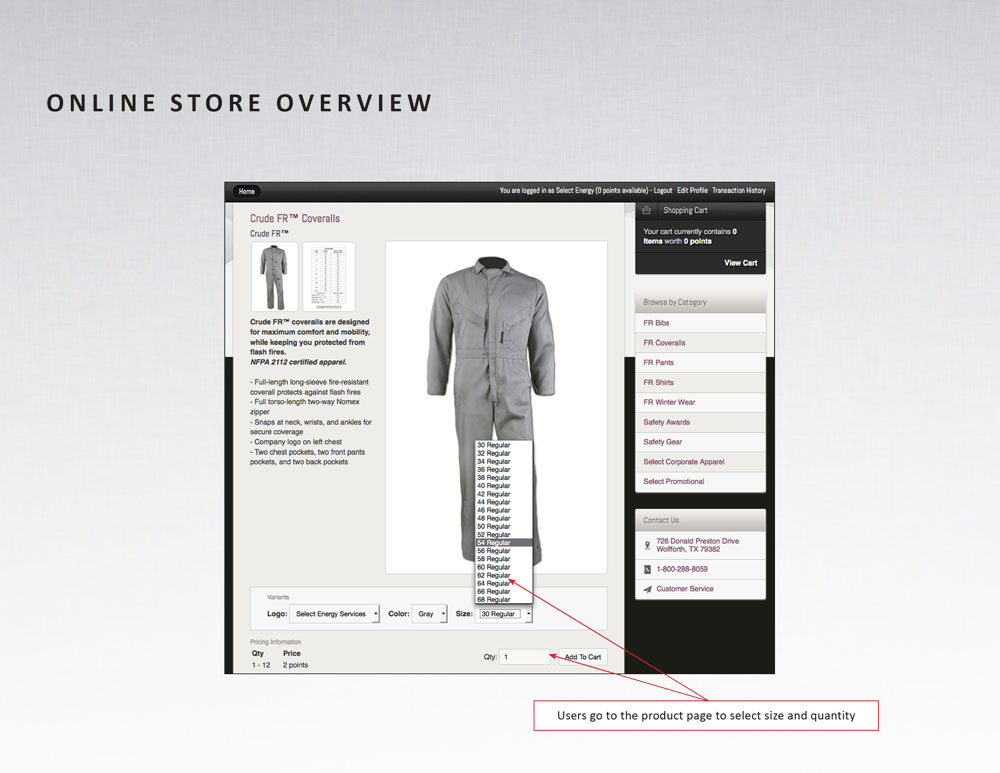

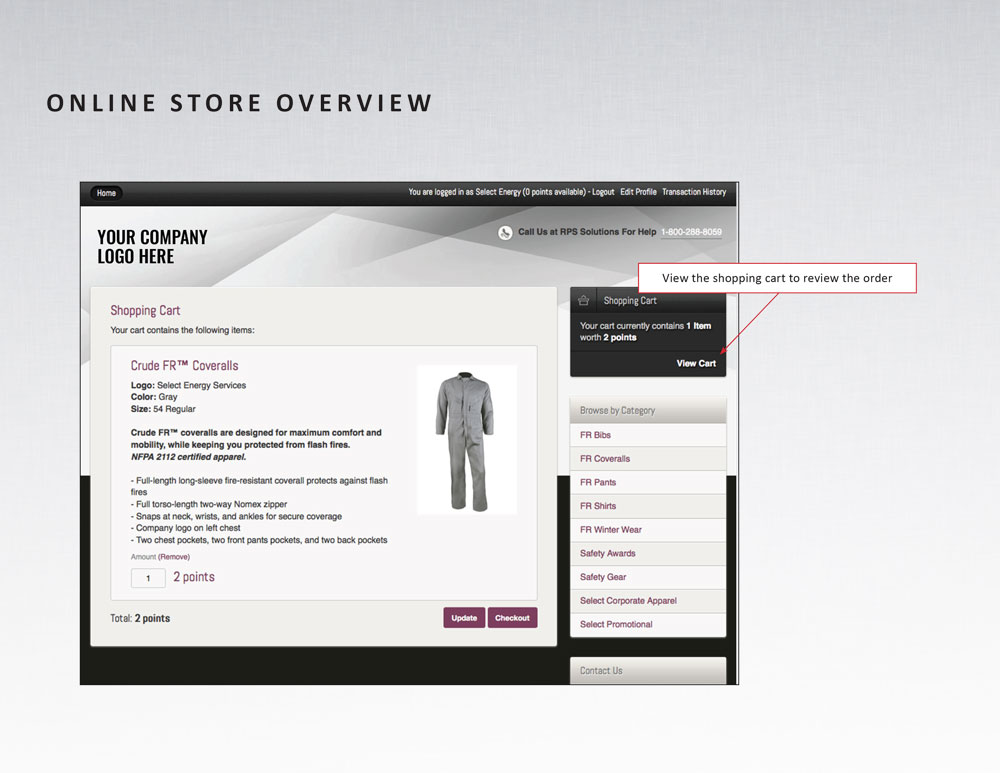

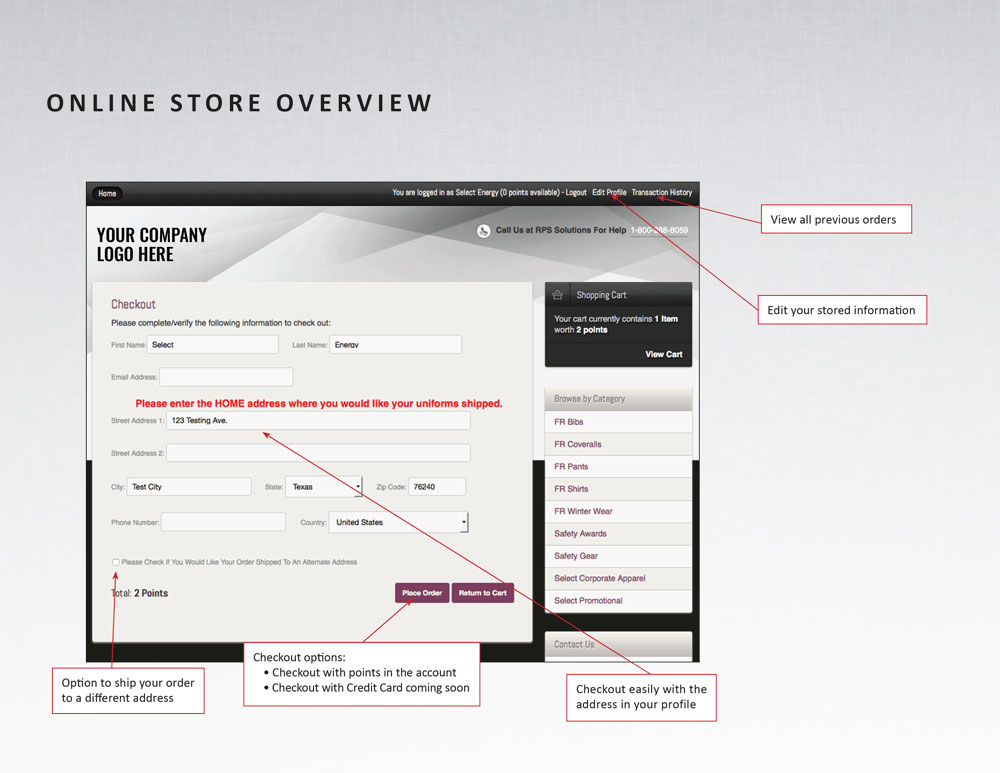

E-COMMERCE STORE SAMPLE SETUP